Master Models Tooling Paste Epoxy Resin Materials Packing 10kg 15kg 20kgs

Product introduction

This product is a two-component epoxy resin imported raw materials, after mixing, apply on the surface of model, after curing on nc machining can be processed into the required model, according to different design requirements for glue, curing content has excellent machining performance, milling, planing, cutting, drilling, and other processing, without a bit wear in the processing, processing and good surface finish and curing is exquisite, knife won't crack, easy to burnish, easy to repair, easy modification, size stability, non-toxic environmental protection, high dimensional accuracy, and reduce the mould cost, etc.

Product main properties

This product is a two-component materials, by automatically output device fast coating model, single coating thickness can be up to 40 mm, reaction put the quantity of heat low, coating and processing when no smell, room temperature curing can be carried out after a day of machining, machining performance is good, good surface effect, material size stability is good

Product operation process

Given according to the proportion of fully mixing thoroughly, the same color. Try to avoid to produce bubbles, it is best to use vacuum mixer mixing. Strict control, with a thick layer of a coating is not more than 40 mm;If upset, after waiting for curing the second floor. The after curing processing, performance is better. (after curing: 80 ℃ + 8 h or 3 days) at room temperature, curing can be after rough machining, precision work after 3 days;The material of metal, composite structure materials such as sticky relay is extremely strong, mold release agents shall be used for rolling over. Make sure the strength of the support frame, stability and cleanness, machine

Introduction

| Material |

5200A |

5200B |

Mixed |

| Description |

epoxy resin |

curing agent |

|

| mixing ration |

1 |

1 |

|

| Color: |

Brown |

Yellow |

Brown |

| mixed time:500g,25°(min) |

|

|

30 |

| curing time before machining(20-25mm) (hours) |

|

|

6-8 |

| layer thickness (mm) |

|

|

max.40 |

| Density:(g/cm³): |

|

|

0.7-0.8 |

| Hardness(Shore D): |

|

|

65-70 |

| Temperature Resistance(°C): |

|

|

70-75 |

| Coefficient of Thermal Expansion(10-6 K-1): |

|

|

45-50 |

| Compressive Strength(N/mm²): |

|

|

52 |

| Flexural Strength(N/mm²): |

|

|

32 |

| Tensile Strength(N/mm²): |

|

|

26 |

| Package(kg) |

10 |

10 |

|

Characteristics:

easily shaped and machined,fine surface structure

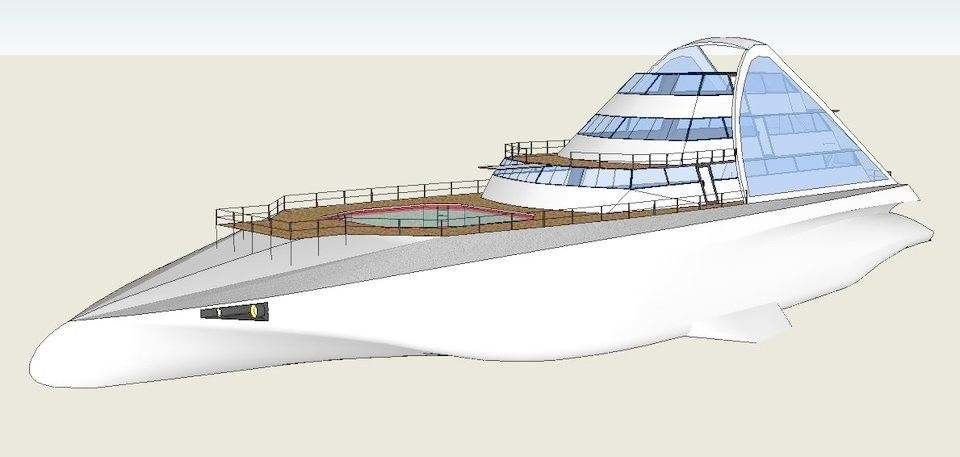

Applications:

yacht model,benchmark model, system and sand-cast model, rapid prototype,etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!