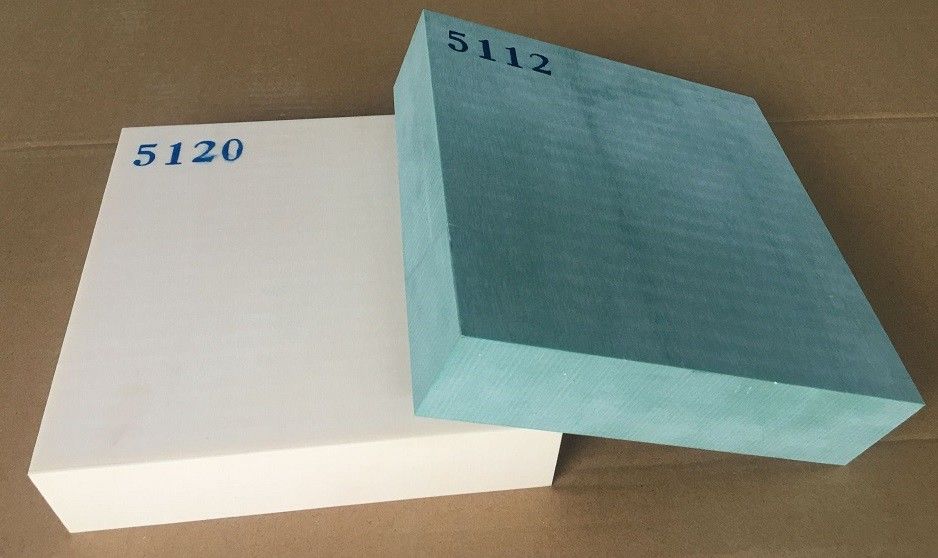

Shore D 82-85 Hardness Density 1.25 Epoxy Tooling Board / Foam Board For Model Making

Lihong Group has been engaged in machinery and tooling business in China for many years. Under our group, we have our own factories as follows:

1. Polyurethane and epoxy plate mold material factory.

2. Polyurethane board is a high quality high-performance board.

3. Research and development center of automation and customized equipment of big brands.

Our comprehensive experience and professional team can provide complete solution support for the following production lines:

1. Polyurethane sheet production line.

2. Epoxy adhesive production line

3. Resin plate processing line.

4. Bonding automation equipment and technical support

As a professional resin plate material, we have collected some large foreign factories, arranged the order quantity of FCL or LCL shipment, and most importantly, we can do a very careful inspection before shipment. We are willing to provide excellent service for your business.

We hope that in the coming days, we can adhere to the principle of "honesty first" to do better. We welcome customers from all over the world to cooperate with us and look forward to your visit. We sincerely hope that we can work together to establish a mutually beneficial relationship, we believe that the right start is the right solution!

Introduction

- Tooling boards are useful for creating durable, reusable tools, prototypes, models and patterns with a CNC machine for use in the motor sport and automotive industries. Selecting the most fit for purpose tooling board will reduce residual particles for easy cleanup, have excellent dimensional stability and maintain tolerances even when exposed to temperature and humidity extremes.

- Tooling boards, also known as modeling boards and machinable slabs, are typically made from filled polyurethane and they exhibit very high dimensional stability and low density. Tooling boards take the place of wood and metal in master models, prototype tooling, patterns, molds, jigs and fixtures. They are lighter and more economical than steel and aluminum. They also do not suffer from the grain and poor dimensional stability of wood.

-

we are also specialists in dimensional checking fixtures to control the manufacturing process of all types of parts of the industrial sector, more particularly the automotive sector.

All our production process - design, manufacture and certification - is done in-house, to control it perfectly.

- Modeling boards are useful in numerous applications including patterns, master models, and presentation models.,foundry patterns, metal forming applications, jigs, and checking fixtures, yacht models,wind power and craft models...etc.

- High temperature cnc machining epoxy casting resin tooling board

Description

| Density:(g/cm³): |

~ISO1183-1:2012 |

1.25 |

| Hardness(Shore D): |

~ISO868:2003 |

80-85 |

| Compressive Strength(N/mm²): |

~ISO604:2002 |

90-100 |

| Temperature Resistance(°C): |

~ISO075-1-2013 |

75-80 |

| Coefficient of Thermal Expansion: |

~ISO11359-1-2014 |

35-45 |

| Flexural Strength(N/mm²): |

~ISO178-2010 |

80-90 |

| Dimension(mm) |

|

(L*W)1000*500*50/75/100

(L*W)750*500*50/75/100

|

KEY PROPERTIES

1. Good styrene resistance

2. High compressive modulus

3. Good amine resistance

4. Very good compressive strength

5. Processing and No dust

6) Good abrasion resistance

7) Resistant to dry ice cleaning

8) Low coefficient of thermal expansion

USE

1. Checking fixtures for metal par

2. Models and molds for polyester applications

3. Models and molds for composites applications

4. Hammer tools

5. Vacuum forming tools

6. Foundry models

7. Foundry pattern plates and core boxes

8. Car fixture

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!