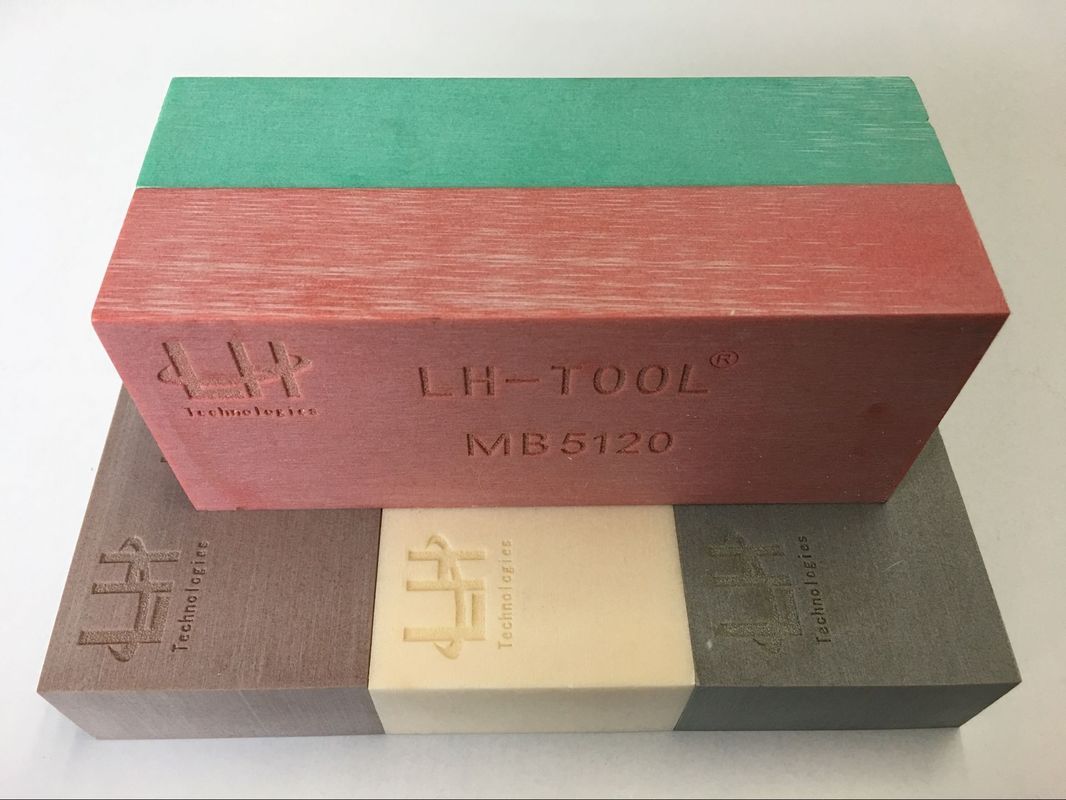

MB5120 Polyurethane High Density Model Board Size 750mm - 500mm 1000mm-500mm

DESCRIPTION

Tooling board has a high edge stability, small thermal expansion coefficient, low dust formation when being machined, no known physiological effects and odeurs or smell. The range consists of 15 different types, varying in density between 600 - 1300 kg m3. There are 20 different dimensions to a maximum of 1500x500 mm and thicknesses of up to 150 mm are available. Larger blocks can be achieved when bonding several blocks to each

other.

Epoxy Tooling board, the toughness, environmental protection, hardness, size stability, temperature tolerance, physical properties such as compressive strength, bending strength is quite good.

We are quietly supporting these industries, automobiles, high-speed rail, shipbuilding, aviation, ceramics, foundry industry and daily necessities manufacturing and related industrieschecking fixtures, mold, wind power and yacht . Maybe we are also suitable for your product, can try, may have unexpected harvest.

KEY PROPERTIES

1. Easy workability • High dimensional stability

2. Cost effective • Good compressive strength

3. High Temperature and chemical resistance • Large sheet sizes available

4. Smooth, non-porous surface finish • Low coefficient of thermal expansion

USES

1. Design studies

2. CNC program proving/testing.

3. Building Landscapes/Features in architectural and scenario models

4. Forming a mould tool for prototyping short runs of composite parts.

5. Use for jigs, fixtures, foundry patterns, core boxes.vacuum forming molds and all kinds of models.

Description

| Density:(g/cm³): |

~ |

1.25 |

| Hardness(Shore D): |

~ |

84 |

| Compressive Strength(N/mm²): |

~ |

92 |

| Temperature Resistance(°C): |

~ |

80 |

| Coefficient of Thermal Expansion: |

~ |

48 |

| Flexural Strength(N/mm²): |

~ |

60.5 |

| Tensile Strength(N/mm²): |

~ |

30.2 |

| Dimension(mm) |

|

(L*W*H)1000*500*50/75/100

(L*W*H)750*500*50/75/100

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!