Modeling CompositeTooling Board For Car Industry Application - Moldling - Car Checking Fixture

Advantages of epoxy tooling board

High dielectric strength

Radiation resistant

High tensile strength

Low cold flow or creep

Chemically resistant

High impact strength

Introduction

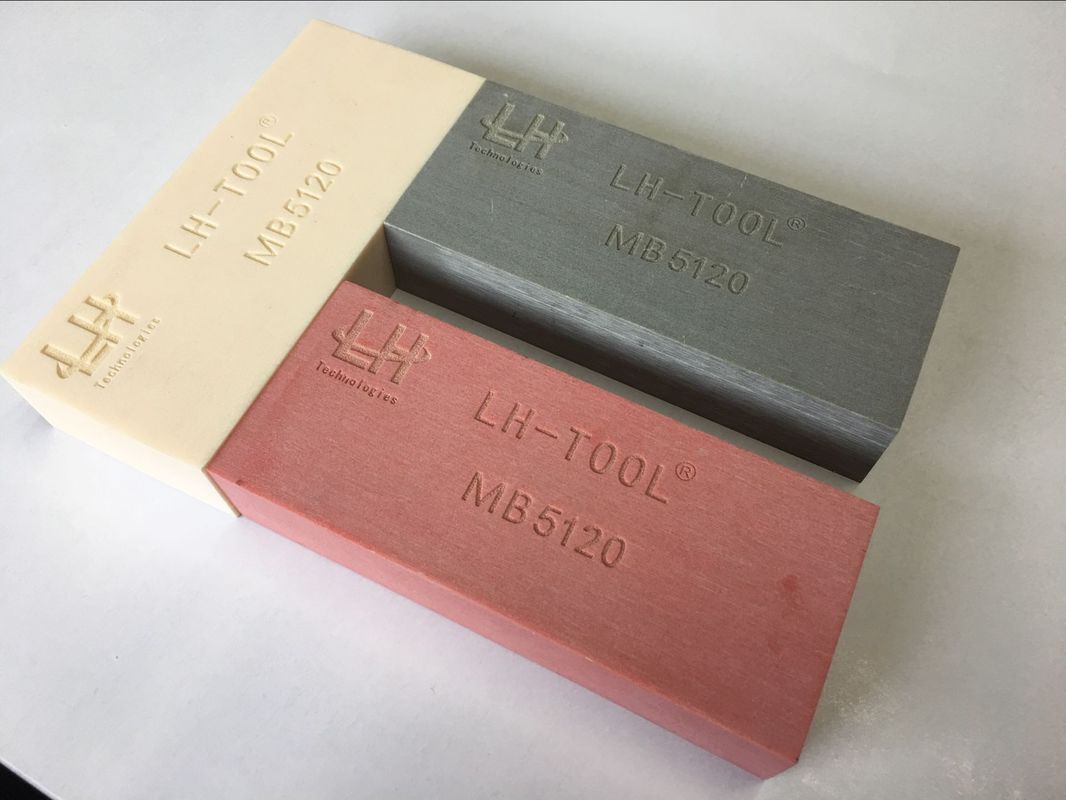

LH Tooling boards take the place of wood and metal in models, patterns, molds, jigs and fixtures.

They are lighter and more economical than steel and aluminum. They also do not suffer from the grain and poor dimensional stability of wood.

Tooling boards can be bonded together to form larger blanks and large blocks from which models or tools can be CNC-machined. The boards are easily mechanically workable with low dust formation.

Tooling boards are useful for creating durable, reusable tools, prototypes, models and patterns with a CNC machine for use in the motor sport and automotive industries. Selecting the most fit for purpose tooling board will reduce residual particles for easy cleanup, have excellent dimensional stability and maintain tolerances even when exposed to temperature and humidity extremes.

Modeling board,tooling borad,epoxy tooling boards and polyurethane tooling baords are heavily used in the automotive industry as well as other industries where prototyping and modeling work is required.

LH Tooling board,modeling board, epoxy resin board,PU board, polyurethane tooling board ,Processability Same As Renshape, NECUMER,RAMPF (RAKU-TOOL),AXSON (LAB),HUNTSMAN etc.

We are also specialists in dimensional checking fixtures to control the manufacturing process of all types of parts of the industrial sector, more particularly the automotive sector. All our production process - design, manufacture and certification - is done in-house, to control it perfectly.

Application

1. Master pattern,Modling • Prepreg CF autoclave cured

2. Checking fixture,jig • Foundry,Casting

3. Automobile model • Protyping,patterns

4. Vacuum forming,thermoforming

General Questions

1. Q: Can you give me a discount price?

A: It is depending on the volume. The larger the volume is, the more discount you can enjoy.

2. Q: Why is your price a bit higher than other Chinese suppliers?

A: To meet the requirement of different customers and areas, our factory manufactures various kinds of quality for each item at a wide range of prices. We can offer the products of different quality levels depending on customers’target price.

3. Q: How can I get a sample?

A: Normally small samples (sizes not larger than 130*60*30mm) can be sent free of charge and customers just needto bear a little shipping charge, or you can provide your DHL,FEDEX,UPS courier account number to us. For bigger sizes, it depends.

4. Q: How can you guarantee the quality of mass production is same with the sample sent to me before?

A: We can guarantee the quality of mass production as the sample sent to you

5. Q: How can you deal with quality issues that customers feedback after receiving thegoods?

A: We will follow below steps to solve the quality issues the may occur.

1) Customers take photos of unqualified goods and then our sales staff will send them to Engineering Department toverify.

2) If the issue is confirmed, our sales staff will explain the root cause and take corrective actions in coming orders.

3) Finally, we will negotiate with our customers to make some compensation.

6. Q: What is the payment term?

A: Our normal practice: 50% deposit of total amount before production, and 50% balance payment before shipment.

7. Q: What is the lead time of production?

A: 3-15 working days starting from the receiving date of the deposit.

8. Q: What is the manner of packing?

A: All goods are packed in a sustainable manner(Standard Export Package).

l Sheets and rolls: All sheets and rolls are carefully packed with protective PE film, plastic wrap, corner support, and iron strips etc. to ensure the safety of long-distance transportation. Rolls will be in protective PE Bubble Bagadditionally.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!